Innovative Solutions

Explore our cutting-edge solutions designed to drive efficiency and innovation in your industry.

Quality Assurance

We prioritize quality at every step, ensuring our products meet the highest standards.

Sustainable Practices

Committed to sustainability, we integrate eco-friendly practices into our operations.

About Us

About Maruti Engineer – Specialists in Rotary Broaching Solutions At Maruti Engineer, we pride ourselves on being a trusted manufacturer and supplier of rotary broaching tools built for today’s advanced machining environments. With years of expertise in precision engineering, our mission is to deliver tools that not only meet but exceed the expectations of machinists and manufacturers worldwide. Our broach range includes internal hex broaches (3.5 mm, 5 mm, 10 mm) and square broaches (10 mm), all made from high-quality High-Speed Steel (HSS) and designed with an overall length of 50 mm. These tools are engineered for compatibility with all standard rotary broaching holders and are tested for use in CNC lathes, milling machines, and conventional lathes. We understand that modern manufacturing demands efficiency, reliability, and accuracy. That’s why our rotary broaches are developed to deliver consistent results in high-speed production environments, ensuring your components are machined with flawless geometry and smooth finishes. Our Commitment to Excellence Continuous investment in R&D and precision machining technology. Manufacturing tools with strict quality control standards. Offering solutions that reduce downtime, lower costs, and increase productivity. Providing customer-focused support and technical guidance. From small workshops to large-scale manufacturing facilities, Maruti Engineer’s rotary broaching solutions have become the preferred choice for those who value performance, durability, and precision. Our goal is simple: to be your long-term machining partner, delivering tools that enable you to stay ahead in a highly competitive industry.

Whether small or big, we respect all our patrons and every care is taken to offer them a hassle-free and a pleasant business experience. We also deliver our orders in economic order quantities as well as in bulk and as a rule, our services and product’s quality always remains the same, apart from quantity or specification desired. In order to meet the off-hand need of our patron, we keep a wide range of standard items of outlets, pipe fittings, flanges, outlets and pipes from sizes ½” to 24”. Patrons’ need for special items is created with finest standards at a specific time. Equipped with this strength, Maruti Engineers is mounting nationally and internationally to place it in the top position.

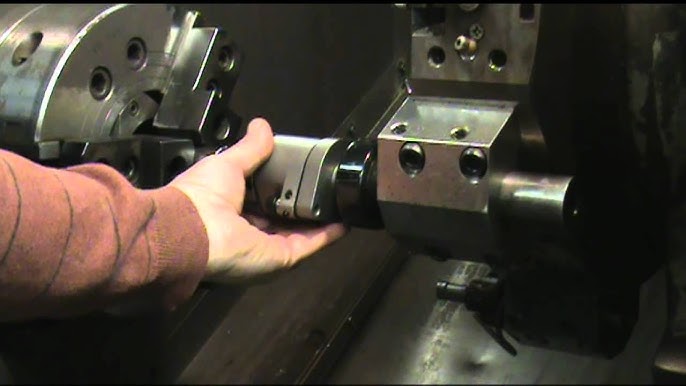

At Maruti Engineer, we manufacture and supply high-precision rotary broaching tools designed for demanding machining applications. Our product line includes a wide range of Internal Rotary Broaches such as Hexagonal (3.5 mm, 5 mm, 10 mm) and Square (10 mm) profiles, each built from premium High-Speed Steel (HSS) to deliver superior strength and cutting performance. Every broach is crafted with an overall length of 50 mm and is compatible with all standard rotary broaching holders, making them a versatile solution for multiple machine setups. Whether you are operating a CNC lathe, milling machine, or a conventional lathe, our broaches ensure accurate, repeatable results across a wide variety of materials. By integrating advanced broaching technology into your operations, you can achieve cleaner finishes, faster cycle times, and reliable performance, even on complex components.

Rotary broaching is a modern machining process that transforms how profiles are cut inside a workpiece. Here’s how it works: The rotary broach tool is mounted in a specialized holder aligned with the workpiece centerline. As the machine rotates (CNC, milling, or lathe), the broach is set at a slight angular offset. This offset causes the cutting edge to “wobble” or oscillate into the material. With each revolution, the tool removes a tiny chip until the full profile—whether hexagonal or square—is precisely formed at the required depth. This method is like pressing a shape into material while gently twisting it, but with the precision and control of modern machining. Rotary broaching allows you to produce accurate internal forms quickly and efficiently, without the need for secondary operations or heavy broaching presses.

Built to Last, Engineered for Strength

Our steel products are the backbone of countless structures, ensuring reliability and performance.

- Employees

- 0

- Clients

- 0

- Years Of Experience

- 0

- Products

- 0

Advantages of Rotary Broaching

- ⚡

Speed & Efficiency

Achieve the desired profile in a single pass, drastically reducing machining time.

- 🛠

Machine Compatibility

Works seamlessly on CNC lathes, milling machines, and conventional lathes without requiring specialized broaching presses.

- 📏

Precision & Versatility

Capable of cutting internal hexagonal and square shapes with high accuracy, including blind holes that traditional broaches cannot achieve.

- 💪

Durability

Manufactured from High-Speed Steel (HSS), ensuring long tool life and reliability, even in high-volume production.

- 💧

Optimized Cutting

Works best with proper coolant/lubrication, correct pilot hole sizing, and alignment, delivering smooth surface finishes with minimal wear.

With the right setup, rotary broaching provides higher productivity, lower costs, and cleaner results, making it an essential tool for industries such as automotive, aerospace, medical device manufacturing, and precision engineering.